So, what seems like it was eons ago now, way back in 2012, the National Railway Museum in York England was preparing for the 75th anniversary of the London & North Eastern Railway’s A4 Pacific locomotive Mallard setting the world speed record for a steam locomotive on July 3, 1938. I’m not going to get into the debate as to whether Mallard went 126mph or not, or whether others went faster on undocumented runs, because frankly, its impressive however you slice it. If you’ve ever been on the footplate of a steam locomotive when its going, you understand why!!

As part of the celebrations of the 75th anniversary in 2013, the NRM decided to host an event they called the “Great Gathering”, where all six of the A4 locomotives which survived into preservation would be brought together. For four of the locomotives, this was a reasonably easy task. 4468 Mallard is at the NRM; and 4464 Bittern, 60007 Sir Nigel Gresley and 60009 Union of South Africa are all preserved in the UK and were all operational in 2013. The last two, 60008 Dwight D. Eisenhower and 60010 Dominion of Canada were however, slightly more complicated. Both of these locomotives had been donated to the respective national railway museums of the USA and Canada in Green Bay Wisconsin and Montreal Quebec in the 1960’s after they were retired. Suffice to say, shipping a pair of irreplaceable and heavy pieces of railway history home for less than a year was not a cheap or easy task. On top of this, both Dwight D and DoC had gotten tired in their time on display. Both were in need of some care, as Dwight had been repainted without a lot of consideration for accuracy, and DoC had been stored indoors, but not climate controlled, and had damage to the streamlining from a shunting accident.

Dominion of Canada being shunted on August 18, 2012 in the Exporail yard to get lubrication into all the axles before loading to ship to the UK.

Dominion of Canada being shunted on August 18, 2012 in the Exporail yard to get lubrication into all the axles before loading to ship to the UK.

UK heavy load specialists Moveright International were brought in by the NRM to ship the two locomotives home to the UK for the Great Gathering, and to be cosmetically restored by experts in the UK. To do this, thanks to the more generous loading gauge in North America, the locomotives could be loaded on top of heavy load flatcars and moved by rail from Green Bay and Montreal to Halifax Nova Scotia, where they would be loaded onto a roll-on/roll-off ship used to ship cars and heavy equipment, and brought back to the UK, where they could be moved by road to York and Shildon for restoration. Moveright has a great set of photos of the moves on their Flickr page.

This heavy move caught my interest as someone with a foot squarely planted in both Canadian Railways and UK Railways and their respective preservation scenes. Since the first time I went to Exporail as a kid, a British Locomotive named Canada was one of my favourites, so seeing her make a big move, and get spiffed up to boot was a big deal for me. But, i don’t model modern railroads (despite being in my mid-late 30’s, my modelling interests are stuck in the 1950’s, go figure right?). Despite this, it’s an awesome looking oversize load, and i decided to model it.

The two cars used to make the shipment were TTX heavy load cars. QTTX131207 is a 60′ flatcar, which was used to haul a container of tools and parts, and the tender. QTTX131344 is an 85′ car with a 70′ deck supported by two span bolsters with two trucks on each span bolster. This car carried the locomotives themselves. These, are cool looking cars, especially the 2nd car. While there are commercial RTR models of heavy load cars out there, none are an exact match for 131344.

131207 was a bit easier, as Intermountain makes 60′ Trailer-on-Flatcar flats, which made a decent starting point. To turn this car into 131207, I sliced off the overhang on the car, built new car sides from styrene, removed the wood deck, and constructed a new plate deck from sheet styrene, with styrene angles for the supports of the overhanging steel deck. I chose an RTR car as i knew it would track, and it meant I didn’t have to produce the underbody detail myself.

Intermountain 60′ Wood Deck Flatcar (picture from Intermountain)

I took a 20′ container, resprayed it, and made decals for the “Grimaldi Group” as the box on the flatcar were labeled. This was the end of the “easy” part of this project.

One of the problems is that models of A4 locomotives are easy to find, in British OO Gauge, or 1/76th scale. They look like beasts when they are loaded up on HO Scale, 1/87th flatcars. Suffice to say, they aren’t readily available, if at all in HO scale (there is a small community of UK HO Scale modellers, but anything they have is far tooo expensive for a project like this). UK locomotives should look reasonably small on top of the flatcar and not dwarf other freight cars around them. So, with a heavy load flatcar which wasn’t available, and a locomotive that is only available in the wrong scale, nothing that can’t be overcome. Fortunately, as I’ve discussed previously here and here, I have access to 3D modelling software and know how to use them to produce 3D printed models. Drawings are readily available from a number of sources for the A4 locomotives, and, the locomotive was covered by a tarp, which means, I didn’t need to successfully model the complex curves of the streamlining, only get the overall shape right so I could tarp it. The tender wasn’t tarped, but its shape was reasonably normal compared to the locomotive.

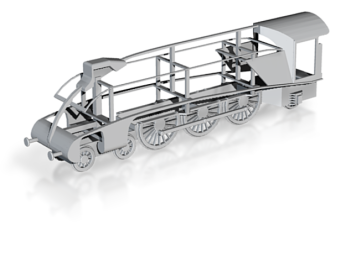

3D Renders of the A4 Wireframe and Tender from Shapeways

Fortunately, while its big, the heavy load flatcar 131344 was a reasonably simple design to draw up, the biggest challenge was designing working mounting for the trucks and making sure it would actually have enough weight to negotiate curves and switches, and run on a layout. It does, I think based on tests at a friends layout, but I’ll be doing more testing with the finished models before I offer them up to sale to others. The design and testing/iterations to learn about how to make the span bolsters work deserves its own post, as it touches on some valuable advice for those looking at 3D design and printing for model railroad projects.

Testing the tracking and weight requirements of the heavy load flatcar QTTX131344

Testing the tracking and weight requirements of the heavy load flatcar QTTX131344

I started this post as a bit of an introducition/history on the project, mostly because I wanted to write a post on what I was working on Saturday night, which was rusting and weathering the deck of the 60′ flatcar, so I can keep that part of the project moving forward. That will be a separate post now that I’ll hopefully write tomorrow on our Holiday Monday, but for a taster, a picture of the car with the tender and container in position is below.

QTTX131207 starting to take shape with the parts container and Tender in position, and the deck rusted up with weathering powders.

QTTX131207 starting to take shape with the parts container and Tender in position, and the deck rusted up with weathering powders.

I started this post with a tale about the Dominion of Canada, and needing some restoration. I’ve already posted this picture as one of my Tuesday Train postings, but I think it warrants brining up the rear markers on this post as well.

British Railways 60010 Dominion of Canada, back home at Exporail after her journey and restored to her original condition as London & North Eastern Railway (LNER) 4489 Dominion of Canada, complete with a bell from the Canadian Pacific Railway mounted in front of the chimney, a very non-British feature!

British Railways 60010 Dominion of Canada, back home at Exporail after her journey and restored to her original condition as London & North Eastern Railway (LNER) 4489 Dominion of Canada, complete with a bell from the Canadian Pacific Railway mounted in front of the chimney, a very non-British feature! CNR D-1 on a test run in Montreal in 1951. From the

CNR D-1 on a test run in Montreal in 1951. From the  Bachmann Doodlebug, image from

Bachmann Doodlebug, image from  HO Scale model of D-1, C-1 & C-2. Picture taken by

HO Scale model of D-1, C-1 & C-2. Picture taken by  Two views of the partly painted Nova Scotia, the room side on the top, and the corridor side on the bottom. The trucks and underframe hasn’t been painted, only primered.

Two views of the partly painted Nova Scotia, the room side on the top, and the corridor side on the bottom. The trucks and underframe hasn’t been painted, only primered. Three views of the underbody details of the HO Scale Model of Nova Scotia

Three views of the underbody details of the HO Scale Model of Nova Scotia Radio Shack 20/40 Watt Soldering Iron. It’s been a fine tool, but long in the tooth now. It will go to Value Village so hopefully someone who needs an iron but can’t afford a new one can give it more use.

Radio Shack 20/40 Watt Soldering Iron. It’s been a fine tool, but long in the tooth now. It will go to Value Village so hopefully someone who needs an iron but can’t afford a new one can give it more use. The new Weller WES51, still waiting to figure out where it’s going to go on the workbench. As part of a cleanup/reorganization happening in the office, it may find a home where it comes out when it’s needed rather than always being on the workbench.

The new Weller WES51, still waiting to figure out where it’s going to go on the workbench. As part of a cleanup/reorganization happening in the office, it may find a home where it comes out when it’s needed rather than always being on the workbench. Milwaukee Hammer Drill/Impact Driver set. Quality tools that have already been handy on some small jobs, waiting on helping build a future layout!

Milwaukee Hammer Drill/Impact Driver set. Quality tools that have already been handy on some small jobs, waiting on helping build a future layout! Nova Scotia in grey primer, showing the little details that are hard to see in unpainted 3D printed material.

Nova Scotia in grey primer, showing the little details that are hard to see in unpainted 3D printed material.